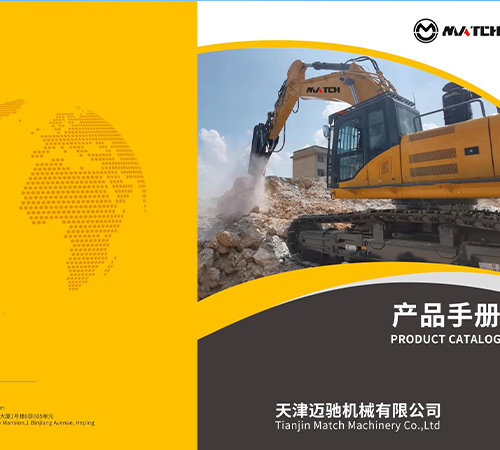

The bulldozer market is even more concentrated than that of loaders and excavators, with a significant market share advantage. The following is a recommended list based on market position and brand characteristics.

1. Globally Leading and Dominant Brands in China:

These brands hold absolute dominance in both the global and Chinese markets, making them top choices for export.

1. Shantui

· Characteristics and Status: The undisputed leader in China’s bulldozer industry, one of the world’s largest bulldozer manufacturers and sellers. Its products are virtually synonymous with Chinese bulldozers.

· Advantages:

· Complete product line: From the smallest 100 series to large and ultra-large crawler bulldozers exceeding 1,000 horsepower, as well as specialized models for wetland, desert, and plateau applications. · Mature and Reliable

Technology: Decades of expertise in the bulldozer industry have honed its technical expertise, and its products are renowned for their durability, power, and exceptional value.

· Self-Supply of Core Components: Shantui possesses mature core technologies for torque converters, transmissions, and final drives (“one wheel, two devices”), which form the foundation of its quality and cost advantages.

· Well-established Global Network: Its overseas sales and service network spans the globe, with a strong presence in developing markets.

· Suitable Markets: It serves all global markets, particularly the Middle East, Africa, Southeast Asia, and the Commonwealth of Independent States. It is the first choice for most overseas buyers.

2. Xuanhua Construction Machinery (under XCMG)

· Characteristics and Status: A long-established Chinese bulldozer manufacturer, now a wholly-owned subsidiary of XCMG Group (XCMG), it carries XCMG’s strategic plan for the bulldozer sector.

· Advantages:

· Brand Heritage: It boasts a long history of bulldozer manufacturing and a solid technical foundation.

· Backed by XCMG: Backed by XCMG’s powerful resources, global sales network, and brand influence, it boasts strong overall strength. ·

Solid Product Offerings: Its products are renowned for their stable quality and reliable performance, and enjoy a good reputation in the mid-to-large tonnage bulldozer market.

· Suitable Markets: It serves the global market, making it a strong alternative to Shantui.

3. Pengpu

· Characteristics and Position: Another established Chinese bulldozer manufacturer with a long history and a solid position in specific sectors and user groups.

· Advantages: Its products are rugged and durable, earning it a loyal customer base.

· Suitable Markets: Its traditionally strong markets and price-sensitive regions.

II. Top International Brands in China (High-End Market Choice):

These brands represent the highest level of global bulldozer technology and primarily target the high-end market.

1. Caterpillar

· Characteristics: A global leader in construction machinery, its bulldozers (such as the D Series) are industry benchmarks. They are renowned for their superior performance, high efficiency, exceptional durability, and advanced technologies (such as advanced control systems and semi-rigid suspension). · Advantages:

Premium brand pricing, unparalleled product reliability and residual value, and the world’s most comprehensive after-sales service and support network.

· Suitable Markets: High-end customers with stringent requirements for equipment performance and availability, such as large-scale mines, energy projects, and infrastructure construction in developed countries.

2. Komatsu

· Characteristics: Another global giant in construction machinery, bulldozers are its traditional strength. They are renowned for their excellent fuel economy, powerful thrust, and precise control.

· Advantages: Leading technology, reliable quality, energy-saving and environmentally friendly, and a well-established global network.

· Suitable Market: Similar to Caterpillar, it primarily targets the high-end market and large-scale projects.

III. Other Distinctive Chinese Brands

1. Yishan (affiliated with SINOMACH)

· Characteristics: One of China’s earliest bulldozer manufacturers, with a long history, it is now affiliated with China National Machinery Industry Corporation (SINOMACH).

· Advantages: It possesses a deep technical foundation and maintains a significant market share in specific sectors.

· Suitable Market: Selected in traditional markets and for specific project procurement.

How to Select and Contact a Brand?

1. Clarify Your Needs:

· Target Market and Operating Conditions: Which region will be exported to? Will it be used for mining, road construction, farmland reconstruction, or forestry operations? This will determine the power and ground pressure (wetland/desert) requirements.

· Power Requirements: What horsepower (HP) do you need for a bulldozer? Options range from 100HP to over 800HP.

· Configuration Options: Do you need special attachments such as a sanitation blade (U-blade), a straight-tilt blade, an angle blade, or a ripper?

· Emission Standards: Does the target country have strict emissions regulations (e.g., European or EPA standards)?

· Budget and Purchase Volume: What is your budget range? Is this a trial order or a long-term purchase?

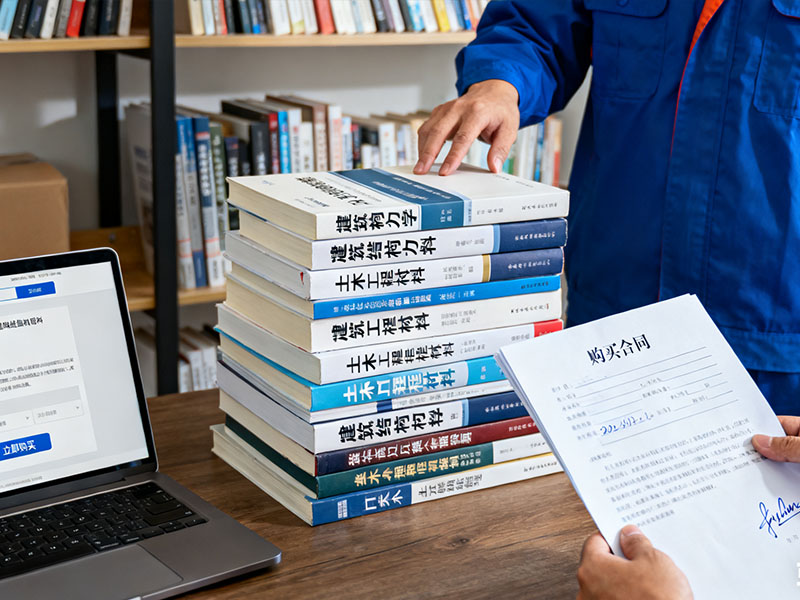

2. Supplier Search Channels:

· B2B Platforms: Search for the aforementioned brand names on Alibaba.com to easily find their official stores or core distributors. This is the most direct and effective way.

· Industry Trade Shows: We highly recommend visiting bauma China. Major manufacturers like Shantui and Xuangong will exhibit their latest products, making it an excellent platform for on-site inspections and negotiations.

· Official Websites: Visit the brand’s official website and look for “International Business” or “Contact Us” to make a formal inquiry.

3. Key Points for Negotiation:

· Qualification Verification: Business license, export qualifications, and relevant international certifications (such as CE certification) are required.

· Technical Confirmation: Detailed confirmation of engine model, transmission type, track specifications, working device configuration, etc.

· After-sales Service: Focus on inquiring about after-sales service capabilities, parts supply cycle, and technical support plans in your target market. Bulldozers are complex structures, so reliable after-sales service is crucial.

· Trade Terms: Clarify pricing terms (FOB/CIF, etc.), payment methods, delivery dates, and shipping details.

Summary and Recommendations:

· For over 80% of overseas buyers, Shantui is the top choice. Its unparalleled product line, price-performance ratio, and global support network make it the most balanced and reliable option.

· For buyers who value XCMG’s background and overall strength, Xuanhua (XCMG) is a strong alternative.

For customers with the most demanding applications, demanding top performance and brands, and with a very generous budget: Contact a Caterpillar or Komatsu sales representative directly.